Project Description

/details

Inert gases are “clean” extinguishing agents with zero effect on the protected goods and on the environment, on global warming in particular.

The gases used are completely inert, colourless, odourless and non-corrosive, hence they are ideal extinguishing agents for use in areas occupied by people. Each gas family acts on the fire with different extinguishing mechanisms (cooling, choking, chemical action, etc.) and has a specific field of application.

The inert gases that Castagna Antincendi supply with their systems are natural products already present in the atmosphere; Nitrogen IG100, Argon IG01, IG55 (argon + nitrogen) and IG541 (argon + nitrogen + Co2)

Tutti gli impianti a gas inerte All CASTAGNA ANTINCENDI inert gas systems are available in versions KIT, pre-engineered or installed on a turnkey basis. We store the gases as compressed gases in 2 to 140 litre cylinders under high pressure (150, 200 or 300 bar).

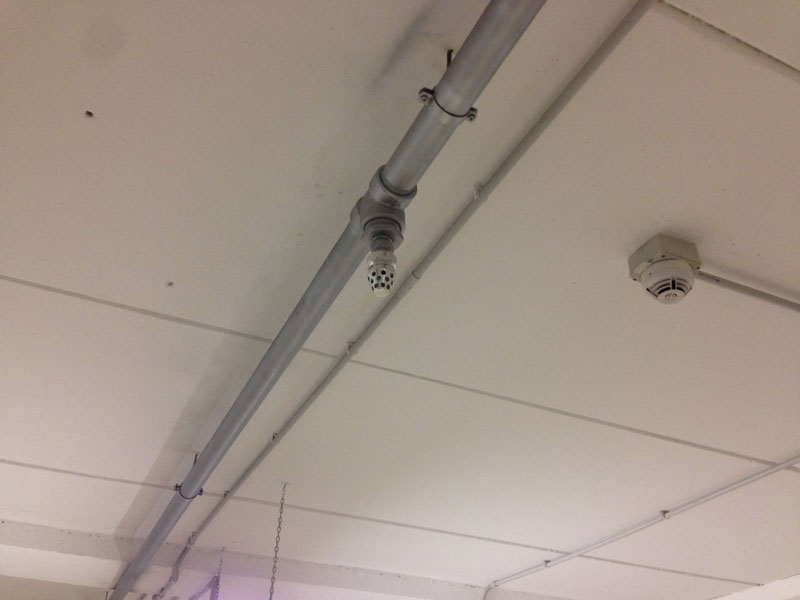

The inert gas fire extinguishing system is composed of cylinder groups, collector, pipe network to transport the gas, brackets/clips and suitable dispensers calibrated following approved hydraulic calculation; this allows propagation of the gas in the environment with the necessary design concentration.

Castagna Antincendi inert gas firefighting systems can also be enhanced with several accessories.

Automatic activation of an inert gas system occurs through different types of smoke detection systems, by means of a manual discharge activation button or manually operating the lever of the pilot cylinder.

To build an inert gas system it is necessary to have our specialised technicians verify the characteristics of the volumes to protect beforehand by means of certified “Door Fan Test”. The test will allow us to determine whether or not it is necessary to install pressure relief dampers equipped with pre-calibrated springs.

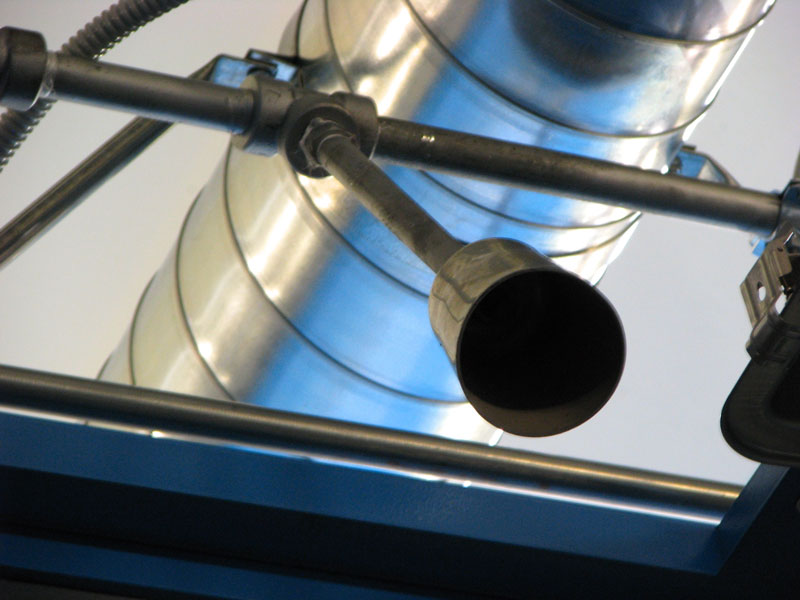

Castagna Antincendi propose the innovative CDT (Constant Discharge Technology) valve in cases where it is necessary to use an inert gas system that has the characteristic of discharging the product in a constant and controlled manner. With the constant discharge of the gas it is possible to drastically reduce the total area (and therefore the number) of the pressure relief dampers.

The gradualness of the discharge often makes it possible to also reduce the diametres of the pipes to lay.

/applications

Data Centre Rooms, data centres, servers, transformer rooms, historical archives, storehouses with significant value, museums, banks, libraries, bookstores, oil&gas, chemical and pharmaceutical companies, equipped containers, turbines, industrial machinery.

/advantages

Eco-friendly “Clean gas”

No residue after discharge so no need for cleanup

Un estinzione rapida e sicura

Independent fire extinguishing system

Technology sustainable over the long term

High safety margins for the people inside

Refilling is simple and inexpensive

No visibility problem after a discharge

Valve with constant discharge technology (CDT)

Certified Door Fan Test

Available according to UNI EN 15004 (1-15), VdS, NFPA and FM standards.

/advantages

Eco-friendly “Clean gas”

No residue after discharge so no need for cleanup

Un estinzione rapida e sicura

Independent fire extinguishing system

Technology sustainable over the long term

High safety margins for the people inside

Refilling is simple and inexpensive

No visibility problem after a discharge

Valve with constant discharge technology (CDT)

Certified Door Fan Test

Available according to UNI EN 15004 (1-15), VdS, NFPA and FM standards.

/details

These types of plants normally use gases present in the atmosphere, are completely inert, colorless and odorless, non-corrosive, and are therefore ideal extinguishers for use in areas occupied by people.

ach gas family acts on the fire with different extinguishing mechanisms (cooling, choking, chemical action, etc.) and has a specific field of application.

The inert gas fire extinguishing system is composed of cylinder groups, collector, pipe network to transport the gas, brackets/clips and suitable dispensers calibrated following approved hydraulic calculation; this allows propagation of the gas in the environment with the necessary design concentration.

Overpressures can be created which will be controlled by using dampers equipped with springs. It is necessary to check the characteristics of the premises by means of the Door Fan Test. Automatic activation of an inert gas system occurs through different types of smoke detection systems, by means of a manual discharge activation button or manually operating the lever of the pilot cylinder.

/applications

Data Centre Rooms, data centres, servers, transformer rooms, historical archives, storehouses with significant value, museums, banks, libraries, bookstores, oil&gas, chemical and pharmaceutical companies, equipped containers, turbines, industrial machinery.